The Need for Digital Twin Software for Cell Towers

Telecom towers have been categorized as critical assets as they provide “enabling functions” across all critical infrastructure sectors. Today, there are over 300 thousand cell towers in America alone which are expected to support an increasingly complex set of requirements from stakeholders. As carriers compete to establish the fastest and largest 5G network, existing cell towers will continue to be key infrastructure assets for the secure and efficient transmission of information, and they’ll be required to carry higher loads.

For their part, tower owners are confronted with multiple challenges: An incomplete or inaccurate inventory of existing assets, how those assets are configured, how to increase tenancy ratio, and what (if any) modifications can be made to better maximize a tower’s performance and meet the constant demand for space.

Traditional tower management efforts involve inspectors climbing the towers to collect measurements. This is both impractical and unsafe, leaving owners with an unreliable as-designed status. With sparse and file-based datasets, unstructured information lacks context and can’t support all the necessary business functions for the complete lifecycle management of their towers.

Digital Twin Software for the Automation of Cell Tower Management

To overcome the inaccessibility and unreliability of tower data, there needs to be one source of truth that consolidates disparate data sources and automates manual processes. A cell tower digital twin can act as this source of truth.

What is a Cell Tower Digital Twin?

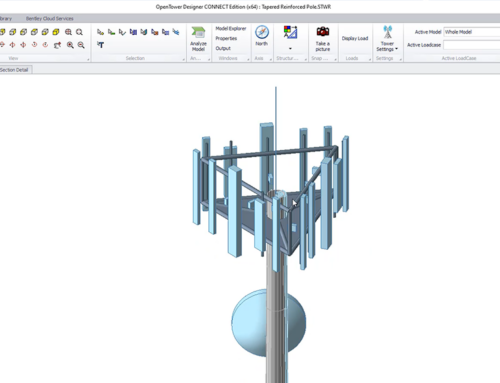

At an early stage, a digital twin was defined as a digital model of a physical asset or space. As it has evolved, digital twin now combines engineering as well as operational and IT data to create an immersive 3D/4D graphical experience.

“Digital Twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.”

The foundational elements of the definition are captured in the first sentence: the virtual representation, the real-world entities, and the processes they represent, and the mechanism by which the virtual and real-world entities are synchronized.

Fig. 1: Fundamentals of a Digital Twin

Why is a Cell Tower Digital Twin Important?

A cell tower digital twin must be comprehensive enough to encompass all essential processes including inspection, visualization, site design, planning, structural analysis, site maintenance, and construction documents. It enables cell tower operators and owners to gain access to actionable insights so that they can better monitor, predict, plan, and react to any required changes through a single source-of-truth.

Fig. 2: The Lifecycle of Cell Tower Digitization

As shown above, a tower digital twin combines five processes to establish an effective tower lifecycle digitization. At a higher level, it can be expressed in two following segments.

- Engineering and construction

- Operations and maintenance

As-Built vs As-Design Tower Information

Current business practices, as well as the economy, revolve around new construction (CapEx) and existing operations (OpEx). However, for cell towers, these two processes are so intertwined that it compels stakeholders to think out of the box to reduce cost and deliver value to their clients efficiently.

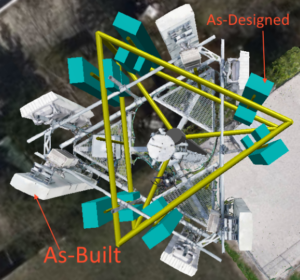

Engineering and construction can be called as-designed. Whereas operations and maintenance can be categorized as as-built. For cell towers, the trend is to use existing cell towers to upgrade technology and accommodate new carriers. So, these business decisions to increase revenue are tightly tangled with the operations and maintenance of existing assets.

Understandably, stakeholders are looking for reliable as-built data to plan, predict, and make critical business decisions. Tower digital twin empowers all stakeholders by reconciling as-designed data (2D, 3D CAD, or BIM) with as-built information. It must be a consistent recurring process as cell towers may go through several updates per year. Therein lies the need for purpose-built software that is intimately familiar with these use cases.

Fig. 3: As-Built vs As-Designed Comparision.

BIM vs Digital Twin, What is the Difference?

As BIM has been evangelized for decades, there is confusion between BIM (Business Information Modeling) and Digital Twin. There are certain similarities like how both create digital models (or replicas) of physical assets. However, the fundamental purpose of Digital Twin is significantly different from BIM.

BIM is used to integrate design and construction processes through different reference points of a single 3D model. It can propagate design changes and reduce errors, calibrate deliverables, manage time, etc. In other words, BIM focuses on the design and construction stages.

Conversely, Digital Twin focuses on operations and maintenance creating a living-breathing model of an operational asset. It brings the current state of the asset (as-built), compares it with the design intent (as-designed), updates asset information, and provides historical references to better predict, monitor, and maintain operational assets. IoT and sensors can notify the user of possible hazards (e.g., fire) and monitor functional states like battery capacity, fuel shortage, etc. As cell towers go through several changes throughout their lifecycle, the digital twin model can evolve for enhanced operational functions with each new stage of change.

Practically, Digital Twin is the generational evolution of the traditional BIM process. It integrates the BIM workflow with operational data to create a living-breathing model. A BIM model is essentially a snapshot of a digital twin lifecycle stage.

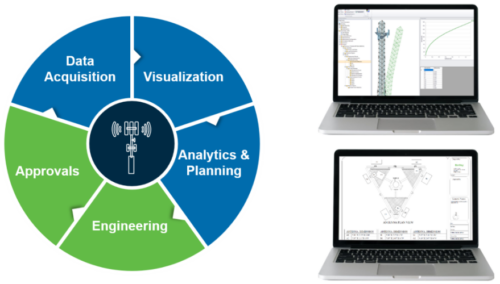

The invention of Digital Twin doesn’t necessarily make BIM obsolete, but it adds the missing layers to convert the engineering and construction data to a living model. Referring to figure 4, the wedges representing engineering and approvals are essentially the BIM component of a lifecycle stage. Also, a digital twin is not dependent on the engineering processes, rather having a design model the corresponding digital twin gets smarter and enables new use cases like the comparison between as-built versus as-designed models, inventory reconciliation, etc.

Fig. 4: Digital Twin Integrated BIM.

For cell tower owners and operators, a digital twin platform can essentially enable interdisciplinary collaboration to keep up with the complex set of requirements to operate and maintain their assets.

Tower Digitization, the Future of Cell Tower Management

Cell tower management processes are a perfect fit for digital twins. It seems to be well known that most tower information consists of 2D and 3D models that are out of date. Mobile network operators are spinning out tower assets they own to rent out spaces and generate extra revenue. However, the lack of existing reliable data and current practices are roadblocks to rolling out an efficient leasing process. Carriers are trying to gain real-time visibility of their space utilization ratio along with construction defects, etc.

A digital twin is timely and fits well to the needs of cell towers digitization efforts. It complements legacy data with photogrammetry to enable a dynamic data source for planning, analysis, and construction.

Tower lifecycle digitization is a paradigm shift and must start with a purpose-built solution to help accelerate this digitization effort reliably and efficiently. If implemented correctly, a tower digital twin can be used for interdisciplinary collaboration and scenario optimization, bringing costs down and making delivery faster. The cost of digitization is a major concern as it includes drones, pilots, etc. Fortunately, new software complemented by computer vision, new drones, and cloud optimization brings the cost down, and the owners and operators have started to realize the benefits of the digital twin.

Learn how OpenTower iQ enables you to maximize the value of your telecom towers. Download our eBook to start taking advantage today.