The global 5G rollout has put pressure on tower owners and carriers to make equipment changes as quickly and inexpensively as possible. Even without the major push for 5G and the tower upgrades that come with it, cell towers need constant changes. Tower repairs and maintenance – including co-locating new tenants, new equipment installation, updating equipment, coverage optimization, and meeting government regulations – are a constant part of the tower lifecycle, and they’re critical to keeping their networks connected.

Engineering serves a key role in maintaining cell towers since every change to a tower’s infrastructure must be overseen and/or signed off by engineering. They must ensure that the proposed changes or upgrades are done safely and accurately, satisfying engineering standards, regulations, and governmental policies. However, due to the lack of reliable data, engineers spend a large majority of their time on asset verification and data reconciliation. This slows implementation and adds more costs to the project’s total, adding significant cost and time to everyday tower operations.

How To Automate Tower Engineering Workflows

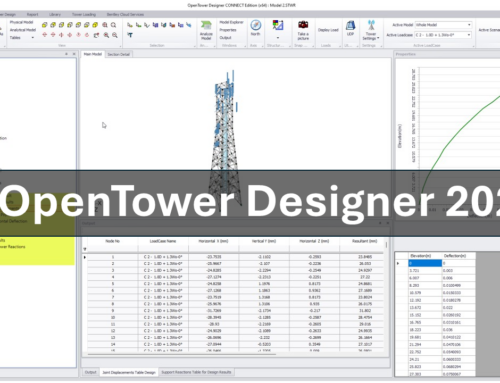

Automating data reconciliation and validation allows engineers to spend their time on the most vital engineering tasks like assigning correct wind loading parameters, verifying software output, tower modifications, etc. Helping engineers refocus on these critical tasks saves time and reduces costs associated with the project. One way to do this is with the OpenTower iQ platform. The platform provides engineers with the automation, collaboration, and reporting capabilities needed for today’s accelerated tower lifecycle.

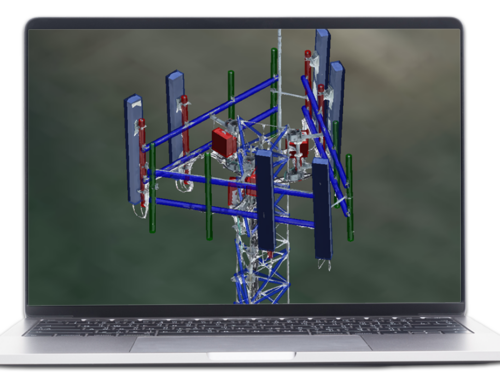

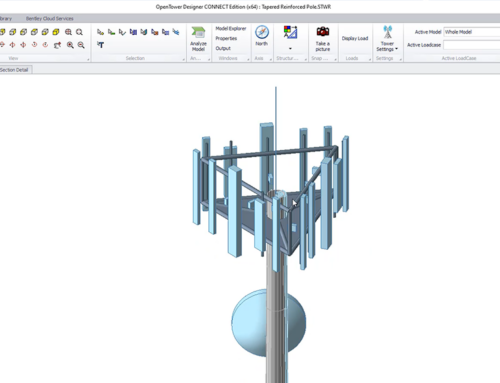

When engineering operations are streamlined with automation and equipment inventory is reconciled with other relevant tower data, tower owners and carriers reduce maintenance costs while gaining access to the data required for all future tower infrastructure projects. OpenTower iQ preserves the history of tower revisions, and users can visualize and compare changes with immersive visualization.

The Benefits of Automating Tower Engineering and Maintenance

Empowering engineers with access to accurate data can do more than reduce the time each engineer is spending on asset verification. It also gives them more relevant data insights. More accurate data lets engineers catch problems and opportunities faster. It also reduces the number of site visits, offers more insights into projects, and speeds up necessary visits by allowing for accurate virtual simulations and calculations. This can create a ripple effect for carriers and tower owners that minimizes loss and maximizes gains. OpenTower iQ also automatically produces reports required for each step of the tower maintenance process. Automating structural reports, including mount analysis and tower analysis along with pre-construction drawings, frees up more time. This allows engineers to shift from generating each individual report to overseeing them instead.

As a critical part of the support system surrounding the tower life cycle, engineers need to be able to do their job quickly and accurately. OpenTower iQ brings efficiency to tower maintenance. This efficiency translates to cost savings of over 60% and time savings of over 90% throughout the maintenance lifecycle of each tower. The result could be millions of dollars saved for carriers and owners.

OpenTower iQ – made by engineers for engineers. To learn more about OpenTower iQ, visit.