One of the priorities of the carriers or mobile network operators is to provide or expand 5G services to their users. 5G is faster, reaching peak data rates up to 20 Gbps and helping millions of people do more with their telecom and data services. It’s bringing the reliability needed to support high-pressure, high-impact industries that need data delivered instantaneously. Combine that with its wider network capacity and lower latency, and it’s easy to see how 5G can impact the lives of millions more users. Naturally, users want 5G, and they want it fast. However, the 5G rollout is slower than anticipated. Among other factors, manual processes involved in designing and upgrading a cell site are key to the slow rollout.

Manual Processes and Data Silos Slow Down the Rollout of 5G

In the current state of the industry, manual processes are involved in almost every step of a tower’s lifecycle. From manually measuring the height of a RAD Center (i.e., tape drop) to ensuring the correct equipment was installed at the correct position, including correct azimuth and tilt, these processes can slow down the tower maintenance efforts to collect and update asset inventory. Each process also usually requires a truck roll (physical inspection), which adds time and money to ongoing projects. Automating these processes can speed things up, but carriers and tower owners not only need the automation tools to make it possible but also need accurate data in place.

Siloed data inherently creates an obstacle to the path of automation and digitization. There is no dearth of data related to towers, and sometimes there may be too much but often contradictory datasets. The problem, however, is the lack of data centralization, making collaboration non-existent. This leaves carriers and tower owners scrambling to find the reliable data they need when they need it. It even mires site planners and engineers working within the same team, hindering how quickly they can work. Tower data, without a single source of truth, remains difficult to track down and even more difficult to be relied upon.

To make things worse, data can also be trapped in paper forms, making them unstructured and even more inaccessible. The lack of high-fidelity data, combined with slow manual processes, can make more truck rolls necessary, significantly adding to both timelines and costs. Every manual action associated with the installation of 5G equipment contributes to the time and resources needed to realize this new technology.

Streamlining 5G Rollout Through Automation

The best way to decimate the number of manual processes needed in cell tower upgrades is to invest in automation and data reconciliation. OpenTower iQ is helping carriers and tower owners realize that change. It uses Digital Twin technology, powered by innovative artificial intelligence (AI) to efficiently create or upgrade its asset inventory to lead the path of automating large chunks of 5G tower upgrades. It allows planners to simulate the proposed installation and helps to reduce construction challenges at the site, saving time and money.

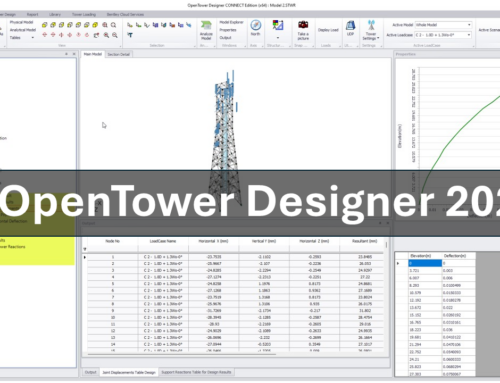

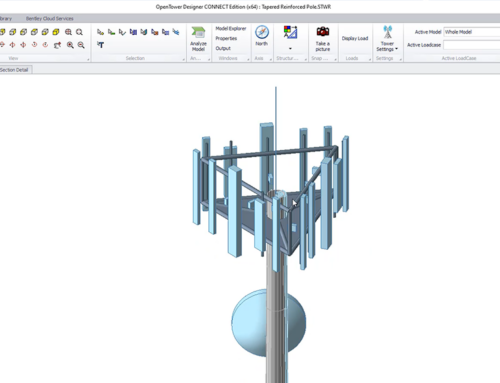

OpenTower iQ can dramatically speed up the data streamline process. Its data acquisition tool can ingest data in different formats, including legacy CAD and engineering data. The program can produce 3D reality models from drone imagery and thanks to its AI, it detects and classify objects, including mounts, antennas, dish, TME, etc. As-built vs. as-designed tools is used to reconcile and build a tower’s source of truth. The result is a streamlined workflow that can automate downstream workflows, including mount and tower mapping, remote site design, structural analysis, revenue assurance, etc.

The current industry practice is to follow a discrete workflow and rely on external vendors to create required deliverables. Not to mention, it takes weeks to finalize a deliverable package. It doesn’t have to be that way. Turf vendors, engineering service providers, carriers, and tower owners can all take advantage of a streamlined workflow. For example, instead of waiting a couple of weeks for a 2D CAD elevation drawing, the software can generate those drawings instantaneously. Planners can simulate a proposed configuration and that can automatically trigger a structural analysis. Engineering service providers can work on the same dataset to review, edit, and stamp engineering reports. The result is an efficient but cheaper and faster workflow.

Telecom industry doesn’t have to settle for the same inefficient manual processes and data silos the industry has become accustomed to. OpenTower iQ provides a solution that eliminates manual and error-prone processes, ensuring quick and timely deployment of the 5G equipment needed for today’s technological demands. When employed through a robust platform like OpenTower iQ, automation saves an enormous amount of time and money, enabling carriers and owners deploy and offer 5G capabilities faster. To learn more about how OpenTower iQ can help you automate and maximize your 5G rollout, schedule a demo today.