OpenTower iQ has been steadily transforming how the telecommunications industry handles tower management, but the digital twin solution didn’t start its life as the best-in-category leader it is today. Hear from Apurba Tribedi, Senior Director of Tower Products at Bentley Systems, about how OpenTower iQ became a powerhouse solution.

Q. How did the concept for OpenTower iQ come about?

A. OpenTower iQ was born out of a project designed to run structural analysis for one of the largest tower owners in the USA. It was a desktop product that relied heavily on data input from engineers. The earliest iterations tried to integrate OpenTower into a client’s existing asset system, but we soon realized we needed to change our approach. Working within the existing asset database also meant our workflow was being limited by the unreliable asset data within these systems. We wanted to create something bigger than that.

Q. What made the existing asset data and workflow processes challenging to work with?

A. A telecom tower’s lifecycle is a bit different from other asset types. In the US and gradually around the world, spaces for towers are typically rented to carriers. With the evolution of technology and the growing need for data, carriers are continuously upgrading their installed equipment on towers. So, the towers typically go through multiple updates each year involving new loading, modifications, engineering review, inspections, etc. When these processes are repeated among hundreds of thousands of towers, the problem of volume occurs and significantly increases the risk of collecting unreliable data.

Q. Does that risk of unreliable data affect a tower owner or carrier’s ability to manage their towers effectively?

A. Yes, it severely affects both the tower owners and the carriers. The more opportunities there are for unreliable data to sneak into each workflow, the more likely they are to see compounding issues further down the line.

Q. Can you give us an example of the risks that unreliable data can lead to?

A. Tower owners typically hire third-party vendors to climb and inspect towers and report the state of the tower and installed equipment. Data collected through these inspections goes through a series of disconnected processes to update a tower’s asset inventory. This process isn’t just tedious and dangerous for the tower climbers; it’s also susceptible to human error. We developed OpenTower iQ specifically to address the need for data reliability within the industry. We wanted to create a program that could serve as a single, accurate source that also minimized the risks common to tower management.

Q. How did you decide to tackle the challenge of unreliable data?

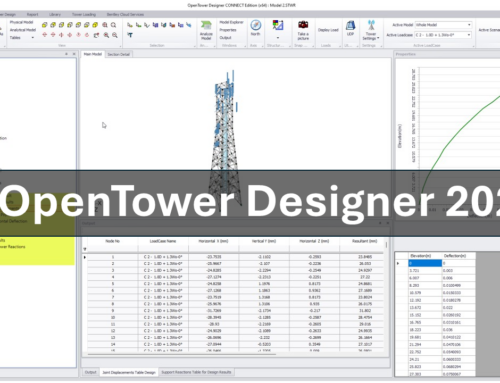

A. We decided to build OpenTower on top of Bentley’s iTwin Platform. Bentley’s photogrammetry software, specifically ContextCapture and OrbitGT, provided the jumpstart we needed to create photo-realistic 3D meshed models. This decision to use digital twins also opened more possibilities for what the software could do. Engaging with other stakeholders—including site management, construction management, and site planning—became a reality.

Q. It sounds like digital twins have given the platform a lot of advantages.

A. Absolutely. We wanted to create an immersive, 4D graphical experience, and representing the entire tower lifecycle in charts and numbers is exhausting for the end user. Digital twins became the source of truth we needed to manage the entire lifecycle seamlessly.

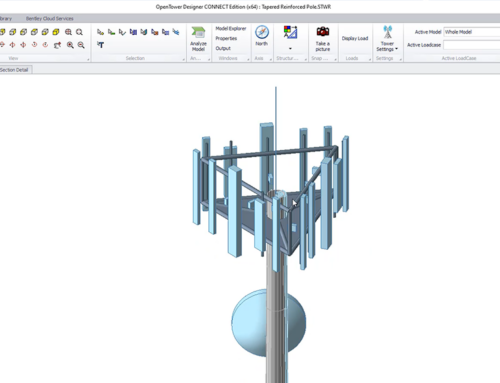

Q. So, how do you turn a tower on the ground into a digital twin?

A. One of our early goals when tackling the unreliable data problem was to reduce the amount of manual input in our processes. We knew we needed a way to scan a tower without having humans climb them to measure each piece. It would make things open to error, even without the massive cost climbing each tower would incur. We turned to drones instead.

With the advancement of drone technology, scanning a tower has become pretty quick and cheap. Drone pilots can typically scan a tower in less than an hour, and it costs less than $300. By combining drone footage and Bentley’s photogrammetry software, we developed a program that could work to visualize, measure, and inspect a tower in minutes. OpenTower iQ can automatically and reliably detect and classify the installed equipment of a tower. This object detection algorithm was a game changer and is done entirely in 3D to measure critical parameters, like azimuth, tilt, etc. By combining iTwin, AI, and engineering, we could unleash new use cases along with a common data environment where all the stakeholders can work collaboratively.

Q. What else did you do to reduce that manual input error you were encountering?

A. We focused pretty heavily on automation. It wasn’t just about reducing error, though. We knew that the right automation could hugely reduce the burden on everyone involved in the tower lifecycle. Removing manual dependency was the key to getting consistently good results. Eventually it helped us to develop other downstream workflow, including drawings, structural analysis, revenue recognition reports, etc.

Q. How has OpenTower iQ changed the telecom industry so far?

A. OpenTower iQ is already a broad-scoped software solution that’s become an industry leader. It connects owners, carriers, turf vendors, and service providers and lets them collaborate in a way the industry had never seen before. As of now, OpenTower iQ has already processed and delivered thousands of towers and is working with almost all major players in the telecom industry. We don’t plan to stop there, either.

Q. Where do you see OpenTower iQ going in the future?

A. We must expand the area of interest from towers to ground equipment, shelters, etc. Our next foray is in the IoT domain. Why do we need to visit sites for operational data gathering when you can have the data delivered right onto your phone along with any analytics? We want to generate real-time signal strength reports by running radio frequency analysis. And soon, we want to expand to other industries, like transmission towers, light poles, wind turbines, and beyond. We’re just getting started.

To learn more about how OpenTower iQ is helping shape the telecom industry, check out our webinar showcasing how OpenTower iQ is helping make the Huawei “Rip and Replace” recall process as streamlined as possible for tower owners and carriers. Check out our website to see how OpenTower iQ can transform the way you approach tower management.