With the recent uptick of telecom M&A, cell towers are changing hands faster than ever, but their inventory and engineering data don’t always survive the trip. New owners often discover that all the tower data available to them is a patchwork of outdated 2D CAD drawings, bunch of PDFs listing equipment installed on towers, hand sketches drawn by tower climbers, etc. After stitching it all together, many questions surrounding accurate asset information bubble up. Since there is no central source of truth to leverage for decision-making, reconciliation along with operating and maintaining tower infrastructure becomes a very difficult and costly process.

So how does one create or access a single source of reliable data to manage lifecycle of towers? Many people think 3D models constructed using images captured via drones are the answer. Some suggest using Building Information Modeling (BIM) workflows can solve the need. Digital Twins, acting as a synchronized replica of the asset, could be a possible solution. But before selecting a solution, consider what is required to maintain modern cell tower infrastructure.

What is Required to Maintain Cell Tower Infrastructure?

A Realistic View of the As-Built Status

The most common tower data accessible to those responsible for maintenance and operations are generally construction document packages and/or idealized engineering models. These are considered as-designed models and are helpful to understand the intent of the construction, including installation of equipment, but do not reflect an accurate depiction of the current status. The moment construction is completed, the fidelity of that data is lost. Was everything installed correctly? Has weather or other aspects of mother nature affected the tower?

To optimize tower tenancy and accelerate important projects like 5G expansion, an accurate as-built model is necessary. This enables owners and operators to make actionable decisions based on the current state of the tower, so truck rolls aren’t wasted and proper maintenance can occur. A tower maintenance system must provide a realistic view of the asset.

Change Management

Continuously updated government regulations, technology evolution, increased tenancy, and the ongoing demands of 5G deployment all mean that tower infrastructure data is in a constant state of change. The majority of this data is recorded manually through various file formats and systems, so it can be very difficult to track these changes. Without maintaining a single source of reality in a central location, the risk of inconsistent analysis increases, and data-based decisions are more difficult—or impossible. A tower maintenance system must be able to handle change management.

Context with Defects and Anomalies

The purpose of a cell tower is to host different appurtenances to properly transmit cellular and wireless signals to those within its surroundings. With this purpose, understanding and evaluating a tower’s stability is essential. The complete picture is needed so those responsible know what the tower needs to be properly maintained. Defects and anomalies happen over time and must be able to be identified, recorded, and communicated. This detection can increase the overall life of a tower and improve performance. A tower maintenance system must be able to include environmental context and structural anomalies.

Accessibility

Teams responsible for tower maintenance are cross-functional and boast a variety of experience levels. All members of the team ranging from climbers, construction crews to engineers, and even upper management need access to critical tower data to perform their function within the tower lifecycle. A system that provides access to all necessary stakeholders is crucial to collaboration and increased efficiencies. Granting and distributing access should also be easy and cost-effective. For anyone with non-engineering responsibilities, an overcomplicated system that demands extensive training is unnecessary. A tower maintenance system must be accessible and understandable to all stakeholders.

A Connected and Open Environment

Tower data can come from a variety of sources in numerous different file types and formats. A truly connected data environment can integrate and visualize as many as necessary data sources to reconcile and paint the accurate status of towers. Integrating and leveraging 2D and 3D drawings, valuable BIM data, drone imagery, maintenance and inspection reports and many other delivers a complete, reality-based model of how a particular tower stands today. This reality-based model provides a clearer picture of the tower, and the insights to make informed decisions about installation of new equipment, operational maintenance, for both the tower owner and carrier, saving time and cost. A tower maintenance system must be connected and open to a variety of data sources.

Purpose Built Solution for Cell Towers

Cell Tower maintenance is unique to many other infrastructure asset types. And the tool that supports the maintenance should be purpose-built around these needs.

Many solutions are built around general infrastructure assets. They can do the job, but they aren’t built solely to support cell tower maintenance and optimization. The tower business model is unique being that it is based around leasing tower spaces to mobile network operators. This means it is crucial to optimize tenancy, be aware of all equipment, and note available space at each step of the workflow. Only a system built and optimized for cell towers holds tools that support this type of workflow, reducing the need for customization.

Utilizing software that is specific to cell towers reduces the need for customization and allows owners and operators to optimize the value they derive from tower infrastructure. A tower maintenance system must be purpose-built to support cell tower workflows.

Automation

The process of reconciling data from multiple sources into a single model typically requires 60-70% of valuable engineering time. Engineers must estimate and make assumptions based on the last analysis or 2D pictures from the last inspection. The lack of automation involved in this process strains resources causing delays and loss of revenue.

Modern technology can help automate these cumbersome processes. Artificial intelligence (AI) and machine learning (ML) can be leveraged to automatically identify tower equipment. Reports can be generated, and analysis can be performed automatically, saving hours of dedicated engineering work. A tower maintenance system must be able to automate manual processes.

What is the Best Solution for Cell Tower Maintenance?

In summary, the following items are required to properly maintain modern cell tower infrastructure:

- A Realistic View of the as-built status

- Change Management

- Context with Defects and Anomalies

- Accessibility

- Connected and Open Environment

- Purpose Built Tools

- Automation

The Tailored Fit: Tower Digital Twin

A digital twin encompasses all the data and functionality necessary to maintain the lifecycle of cell tower asset, including processes involving design and construction. An evergreen cell tower digital twin can enable one accessible, automated view of the truth that is aligned to operational workflows and enables true windows into profitability and value.

A tower digital twin is capable of continuously updating its dataset to remain current and serve all users with the best possible information. It’s economical too. Many of the digital twin software solutions are licensed at the server-level and deliver multi-user concurrent access that is needed for teams across the company to leverage and update the model and collaborate effectively.

Digital twins are a game-changer for the telecom industry. They play a pivotal role in modernizing industry practices by serving as a live model and single source of truth, combining as-designed models, as-built models, and live sensor data throughout the lifecycle.

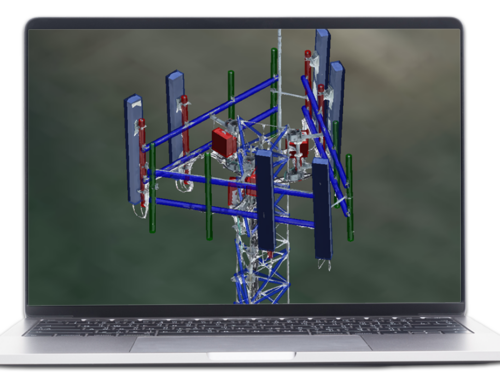

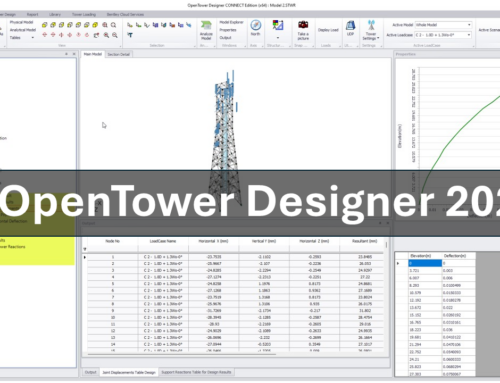

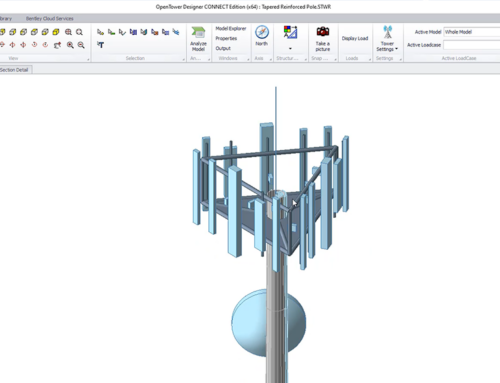

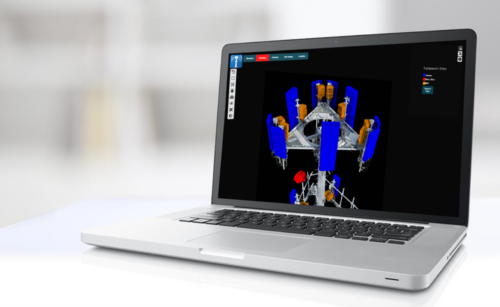

Fig 1: Cell Tower Digital Twin from OpenTower iQ

The OpenTower iQ Difference

OpenTower iQ from Bentley Systems is a cell tower digital twin solution, delivering a single source of truth with visualization, analytics and planning, and engineering capabilities. This provides cell tower owners and operators the data, tools and insights necessary to satisfy all of the requirements for a proper tower maintenance system.

OpenTower iQ creates a realistic view of tower infrastructure, ensuring that the physical asset in the field is accurately reflected in its tower digital twin through every site visit and update. All tower data is digitized, contextualized, and made accessible to necessary parties, creating a true connected data environment. Purpose-built for cell tower maintenance, OpenTower iQ offers the ability to automate the inspection, detection, analysis and engineering resulting an immersive graphical experience along with cheaper and faster maintenance cycles.

The Bottom Line

Too often cell tower owners find themselves lost in a morass of proprietary formats, lacking any single source of truth—and unable to effectively maintain and operate their towers. Force-fitting existing systems to support cell towers is painful, expensive, and limiting. Why treat all assets with a one-size fits all technology approach?

Digital twins are a modern, proven technology designed to build and operate the world’s infrastructure. Leveraging a tower digital twin for communication towers has operational and economic benefits. With Bentley’s OpenTower iQ, telecom companies create a single source of truth, increase the accuracy of tower data, introduce process automation, and improve collaboration. Along the way, they can realize lower costs, less risk, better decision support, and faster provisioning of additional capacity.